Best Exothermic welding services in india. Exothermic welding is a process used for joining similar metals, such as copper to steel or copper to copper. It employs an exothermic reaction to form a molecular bond between the two pieces.

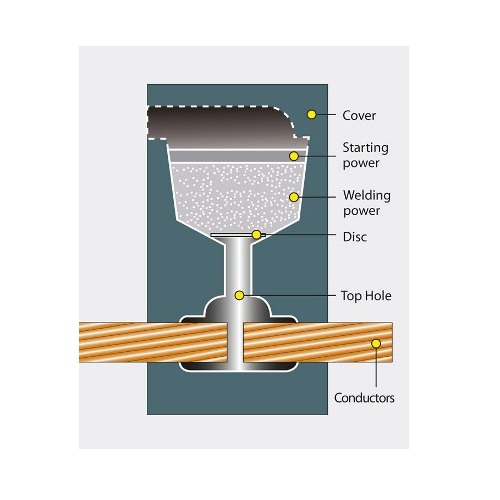

The connection is produced in a purpose-designed graphite mold. The weld employs an exothermic reaction of thermite (powdered metal) to heat the metal. Put simply, the exothermic process involves a chemical reaction that releases heat and requires no external source of heat.

When executed correctly, an exothermically welded connection is homogeneous after cooling, meaning a true weld has been formed and the element s are completely fused together. The connection is permanent, irreversible and requires no additional means to hold it together.

In general, exothermic connections are superior to mechanical connections for grounding due to the permanent bond made between two materials. Especially for use with electrical connections, a reliable connection is key. Exothermic welding dealers in india.

- Maintain a lower resistance over time due to the fused connection.

- Will not deteriorate with age due to a limited susceptibility to corrosion.

- Lifespan exceeds that of the conductors it connects.

- Eliminates any risk of loosening because of the molecular bonding.

- Maintain a lower resistance over time due to the fused connection.

- Will not deteriorate with age due to a limited susceptibility to corrosion.

- Lifespan exceeds that of the conductors it connects.

- Eliminates any risk of loosening because of the molecular bonding.

- Will resist repeated faulty currents.

- Offers the lowest possible earth path resistance.

Mould: Each graphite mould produces a unique type of joint.

Weld Powder: Produce high quality electrical connections between different metals (Copper to Copper, Copper to Steel, Steel to Steel, etc.)

Ignition Powder: Ignition Powder is used to provide initial flame to the weld powder. It is sprinkled on the top of weld powder

Steel Retaining Disc: The disc acts as timing device to allow the welding powder to heat to proper temperature. Steel Disc is designed to contain the exothermic reaction to the upper crucible of a mold until the reaction is complete and ready to welding

Flint Gun / Igniter: Used to ignite & initiate in exothermic reaction

Hand Gloves: Used to provide safety high temperature resistant gloves while working on the exothermic reaction

Handle Clamp: To clamp the two/three part mould together (or) clamping the mould to the surface to which a connection is to be made

Mould Brush: Used for cleaning the scrap on mould after weld joints are completed